The Smart Choice for Product Safety: Foam Protective Packaging Explained

Introduction

In today’s fast-moving world of logistics, e-commerce, and global manufacturing, the need to safeguard goods during transit has never been more important. Foam protective packaging has emerged as a leading solution, providing a reliable, versatile, and cost-effective barrier against the physical risks that threaten fragile, valuable, or sensitive products.

Whether you’re shipping electronic components, automotive parts, or luxury consumer goods, the right protective packaging can mean the difference between a safe delivery and a costly return. But not all packaging is created equal. Let’s explore why foam packaging—especially polyethylene-based solutions—is the smart choice for your packaging strategy.

Understanding Foam Protective Packaging

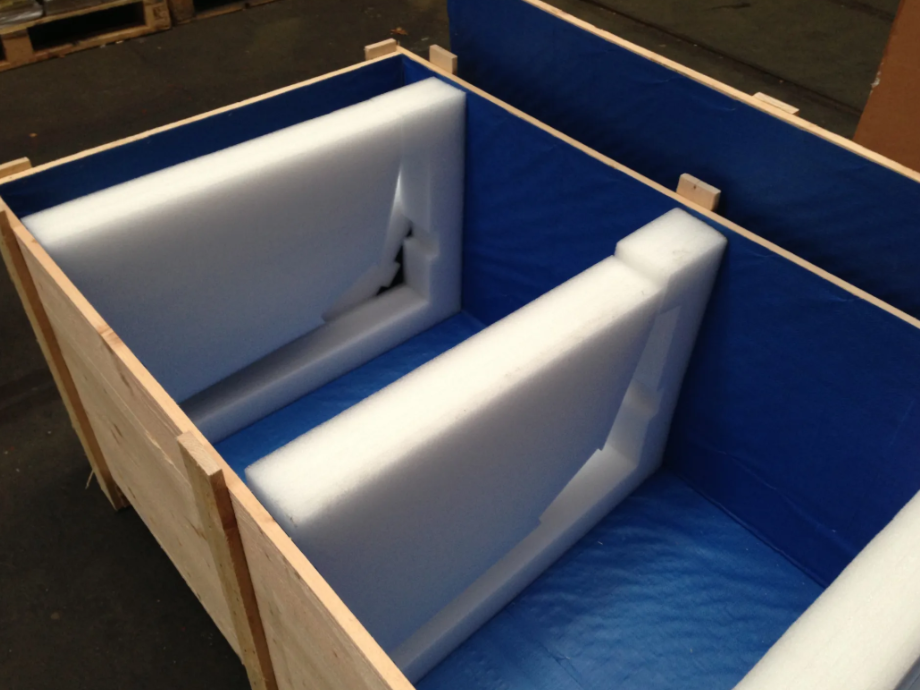

Foam protective packaging refers to a broad category of packaging solutions made from various foam materials such as polyethylene, polyurethane, polystyrene, and more. These materials are crafted into shapes like inserts, blocks, end caps, and die-cut profiles that cushion products from external shocks, vibration, and environmental stresses.

The key advantage of foam is its cellular structure, which acts like a network of mini shock absorbers. This unique construction allows foam to absorb and disperse impact energy, minimizing the risk of breakage during transport. Moreover, its lightweight nature reduces shipping costs while providing substantial protective benefits.

Polyethylene Foam: Engineered Protection for Modern Needs

Among the different types of foam, polyethylene foam stands out for its durability, flexibility, and superior performance in high-stakes environments. Often referred to by trade names like Ethafoam, Stratocell, or Jiffycell Polylam, polyethylene foam is widely used in industries such as aerospace, healthcare, and electronics.

Why Choose Polyethylene Foam?

- Multi-Impact Resistance: Polyethylene foam does not degrade after repeated impacts, making it ideal for multi-trip or reusable packaging applications.

- Chemical and Moisture Resistance: It provides a protective barrier against moisture, chemicals, and temperature fluctuations, which is essential when shipping sensitive products.

- Customizable Colors and Anti-Static Options: Available in black, white, blue, and anti-static pink, it can be tailored for tool kits, electronic devices, and more.

When transporting expensive or delicate items, polyethylene foam protective packaging delivers consistent, repeatable protection that ensures your goods reach their destination in perfect condition.

See also: The Power of Data Analytics: Unleashing Insights for Business Growth

Complete Packaging Systems from a Single Source

Working with a trusted provider like Advanced PP means you get more than just foam inserts. You receive a complete packaging solution—from boxes and cartons to tapes and void fillers—all designed to work in harmony. This approach streamlines the procurement process and ensures compatibility between internal and external packaging components.

For example, a medical device might be housed in a die-cut polyethylene insert, protected within a double-wall corrugated box, sealed with high-tack protective tape, and stabilized with biodegradable bubble wrap. Every element plays a role, and each is engineered to function as part of a comprehensive system.

Benefits of Foam Protective Packaging

Choosing foam protective packaging offers businesses a wide range of strategic advantages:

1. Impact Absorption

Foam materials are designed to cushion and protect items from bumps, drops, and pressure during handling and transit. The structural integrity of foam minimizes the risk of product breakage, helping to reduce return rates and financial losses.

2. Custom Fit for Every Product

Foam packaging can be cut, shaped, and molded to match the exact dimensions of any item. This custom approach not only enhances protection but also improves the unboxing experience for end-users—particularly important in luxury goods and consumer electronics.

3. Reusable and Sustainable Options

High-quality polyethylene foam is reusable, which is ideal for companies seeking sustainable packaging solutions. Additionally, many foam products can be recycled or sourced from materials that comply with eco-friendly standards, helping businesses meet environmental targets.

4. Versatility Across Industries

From e-commerce to automotive, foam packaging adapts to a wide range of products and shipping methods. It can be used for single-use shipping, multi-drop distribution, or even factory transit between production stages.

Applications Across Key Industries

Foam protective packaging isn’t just for one sector—it’s a vital asset for many industries:

- Electronics & Technology: Anti-static polyethylene foams protect devices from moisture and electrostatic discharge.

- Medical & Healthcare: Customized inserts ensure delicate instruments arrive sterile and undamaged.

- Automotive: Durable blocks and inserts safeguard parts during factory transit or delivery to dealerships.

- Retail & E-commerce: Foam packaging enhances presentation and reduces product returns due to shipping damage.

- Industrial Manufacturing: Heavy-duty foam provides structural support for bulky components or machinery.

Advanced PP’s in-house design team works closely with clients to develop bespoke solutions, often reducing packaging material use while increasing performance.

Why Choose Advanced PP for Protective Packaging?

With over 30 years of experience and a strong presence in Manchester, Advanced Protective Packaging delivers high-performance solutions trusted by businesses across the UK. Here’s what sets them apart:

- Local Manufacturing with National Reach: A Manchester-based facility ensures rapid response and short lead times.

- Expert Design Team: Specialists in Nomafoam, Zotefoam, and Plastazote create tailor-made packaging systems.

- Single Supplier Advantage: Boxes, foam, tapes, and bubble wrap—all from one place.

- Eco-Conscious Practices: From biodegradable bubble wrap to packaging that meets UK Plastic Packaging Tax requirements.

- Quality You Can Trust: All products are rigorously tested to meet ISO standards and industry benchmarks.

One logistics manager in Manchester reports a 90% reduction in product breakages after switching to Advanced PP’s foam packaging solutions—a testament to the real-world effectiveness of their systems.

Conclusion: Future-Proof Your Shipping with Foam Packaging

In an increasingly complex and competitive market, businesses can’t afford the risks of poor packaging. Foam protective packaging, especially polyethylene-based designs, delivers consistent results across diverse industries, protecting both your products and your reputation.

Whether you’re shipping a medical scanner, a set of luxury speakers, or a precision automotive part, investing in advanced protective packaging ensures peace of mind from dispatch to delivery.

Choose a partner like Advanced PP to benefit from expert consultation, bespoke designs, and a one-stop solution that combines protection, sustainability, and value. Because when it comes to safeguarding what matters most—foam packaging just makes sense.